The self-cleaning Automatic Filter F490 is pneumatically operated and used for the separation of solids in various different media like seawater, river water or process water. The Filter ensures reliable and continuous filtration in a variety of applications like cooling water cycles or water treatment plants. The filter can operate at very low pressures of only ≥ 0,7 bar and is characterized by an unmatched low backflush rate, a compact design and near maintenance-free operation.

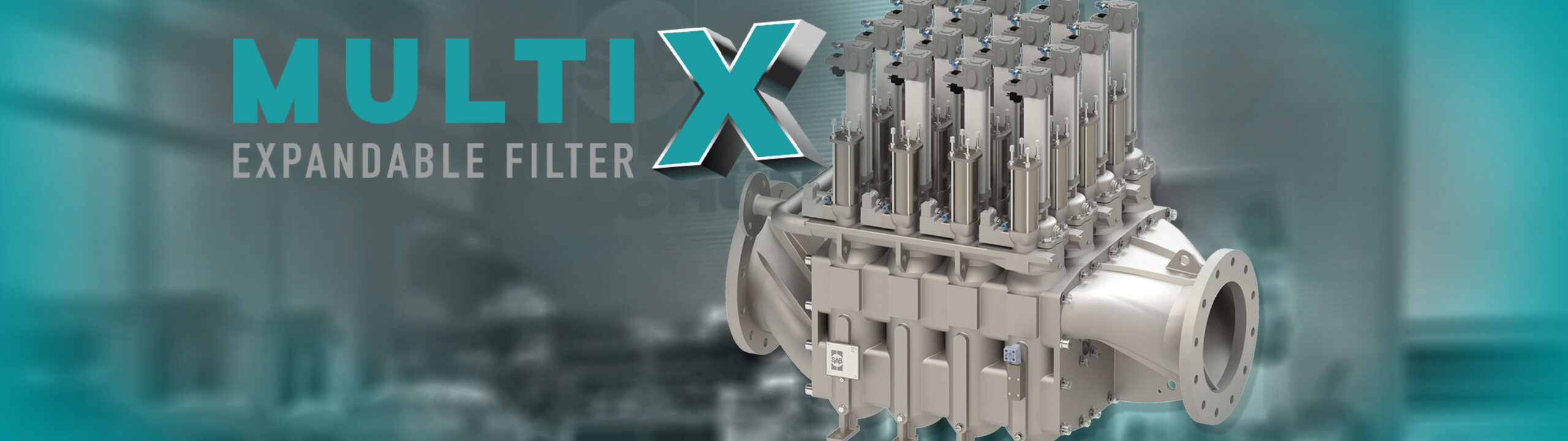

The revolutionary MULTI X design utilizes the advanced Multi-Bernoulli cleaning technology. This technology was invented by Georg Schünemann and combines multiple strainers in one filter housing.

Reliable filtration by using the Bernoulli principle

| In- / outlet | DN100 – DN800 (DIN, ANSI) |

| Housing Material | GGG-40 1.4581 1.4557 |

| Design pressure | 10 bar |

| Volume flow | 50 to 8000 m3/h |

| Strainer insert | Slot wedge wire strainer Basket strainer |

| Grade of filtration | ≥ 40 µm (Slot wedge wire) ≥ 1 mm (basket) |

| Design code and guidelines | AD2000/ EN13445 ASME VIII Div.1 PED/ EAC |

Grade of filtration

GRADE OF FILTRATION

The MULTI X ensures the safe protection of our customer’s applications with a consistently high filtration quality down to 40 μm. The proven Multi-Bernoulli technology warrants a continues and effective filtration even at low operating pressures starting from only 0.7 bar.

Backflush rate

The innovative multi-strainer design allows exceptionally low backflush rates. Less than 1% of the total volume flow are possible and underline the unmatched efficiency of the MULTI X. While maximizing the clean water flow the waste water flow is reduced to a minimum. Possible costs for the storage or disposal of the backflush can be reduced significantly.

Compact design

With its smart and modular design, the MULTI X offers a considerably smaller footprint saving up to 40% of space compared to conventional filter solutions. This compact design based on smaller and standardized components, reduces the required maintenance space and efforts significantly. The flanges are arranged in-line to ensure an easy piping integration without any height offset.

Filtration cycle (Bernoulli prinziple)

Bernoulli‘s principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in static pressure. Georg Schünemann has perfected the utilization of the Bernoulli principle for automatic filters over decades. The distinguishing feature of this filter is the flushing disc, which enables an efficient and contactless cleaning. The cleaning process is completely automatic and requires no manual intervention.

FILTRATION

- During normal filtration, particles accumulate from top to bottom on the inside of the strainer.

- Cleaning begins automatically according to a timed cycle, or after a high differential pressure signal.

PRE-FLUSHING

- During the pre-flushing phase, the flushing valve opens and particularly larger particles are flushed out.

CLEANING

- The flow velocity increases locally around the disc within the gap between the flushing disc and the strainer. Simultaneously the static pressure is reduced in accordance with the Bernoulli Principle and the direction of the flow is reversed which releases the particles from the surface of the strainer basket.

- The released particles are flushed out from the filter via the flushing outlet. Finally, the flushing valve is closed.

- The filtration will not be interrupted during the entire cleaning cycle.

F490

Downloads

Do you have any further questions?

Our team is always available to answer your questions quickly and easily.

Dörthe Nowak

+49 421-55909-75

nowak@sab-bremen.de

Jan Dora

+49 421-55909-53

dora@sab-bremen.de

Nina Neumann

+49 421-55909-32

neumann@sab-bremen.de