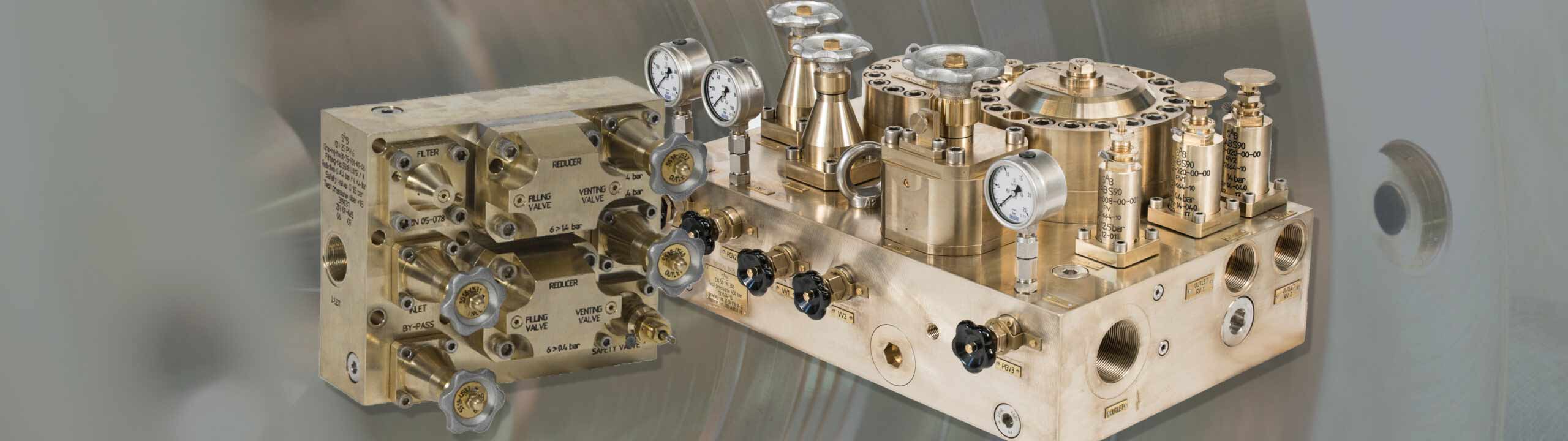

Reducing stations are designed and built to satisfy our customers’ needs. They reduce HP air/gas to LP in a single monoblock housing with all flow paths integrated. All reducing stations can be equipped with integral filter, safety relief, stop, automatic stop, metering and gauge valves. A two stage reduction will provide a more stable outlet pressure even with rapidly decaying inlet pressure. Multi stage reducing station with one inlet and several outlet pressures available provides weight and space saving along with huge reduction in potential leakage paths.

Specifications

| Nominal width | DN6 to DN32 |

| Rated pressure | up to PN 330 bar |

| Operating temperature | -30 to +80°C |

| Operating medium | Compressed air and neutral gases |

| Inlet pressure | 250 bar |

| Installation position | any |

| Connections | Threaded connections |

| Filter mesh | 25 µm |

| Functional test | Pressure reducer (including flow measurement) |

| Body | 2.0967 |

| Internal parts | 2.0967 / 2.0958 / 1.4401 |

| Seals | NBR / PA6.6 |

Inserts and drives

SAB’s pressure reducing stations are 100% custom made according to the specifications. They can be equipped with any SAB standard cartridge valve to suit the functions needed

Do you have any further questions?

Our team is always available to answer your questions quickly and easily.

Vanessa Tietje

+49 421-55909-33

tietje@sab-bremen.de

Christian Viertel

+49 421-55909-0

viertel@sab-bremen.de

Daniel Nagel

+49 421-55909-24

nagel@sab-bremen.de