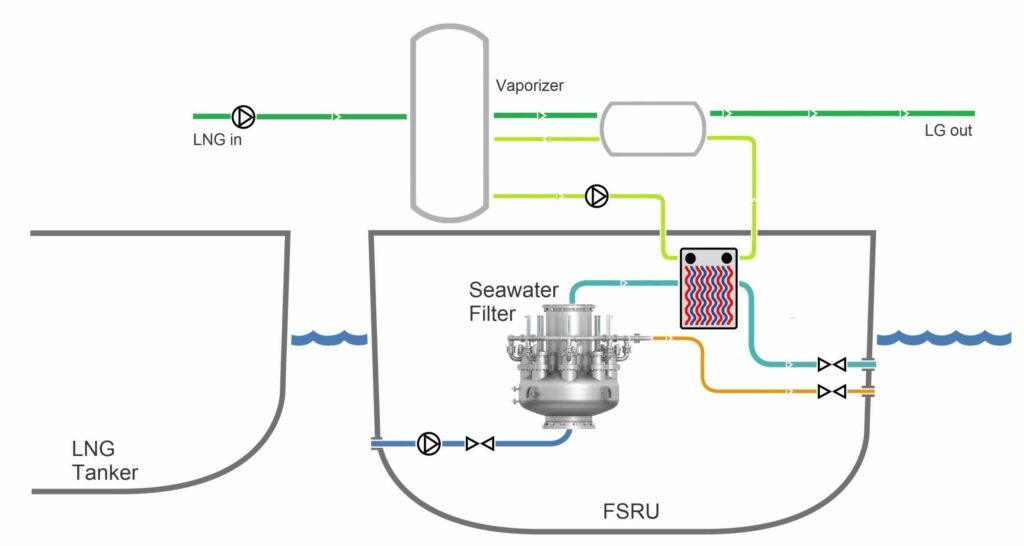

The liquefaction and regasification process plays a key role within the LNG (LNG = Liquefied Natural Gas) value chain. For the liquefaction, the natural gas needs to be cooled down to approximately -164°C. LNG has a volume of about 600 times less than natural gas and can therefore be stored and transported very efficiently. The regasification takes place either on land, or water in a so-called “FSRU” (Floating Storage and Regasification Unit); in both cases, requiring a considerable input of heat. State of the art LNG vaporizer systems use seawater as the heat source. In order to ensure efficient and uninterrupted operation of the heat exchanger and vaporizer cycle, it is necessary to install a reliable and proven seawater filter upstream of the heat exchanger. Based on a large number of references SAB has gained many years of experience for this application.

- Reliable protection spray nozzles

- Elimination of algae and other microorganisms

- Compact design

- Reduced maintenance cost and downtime

Do you have any further questions?

Our team is always available to answer your questions quickly and easily.